So G71 for boring has a couple of differences. If we look back at our G71 External turning cycle we had the following.

- G00 X61.0 Z3.0

- G71 U2.0 R0.5

- G71 P100 Q200 U0.5 W0.0 F0.25

- N100 G00 X21.0

- G01 Z0.0

- G01 X25.0 Z-2.0

- G01 Z-25.0

- G01 X40.0

- G01 X50.0 Z-30.0

- G01 Z-75.0

- N200 G01 X60.5

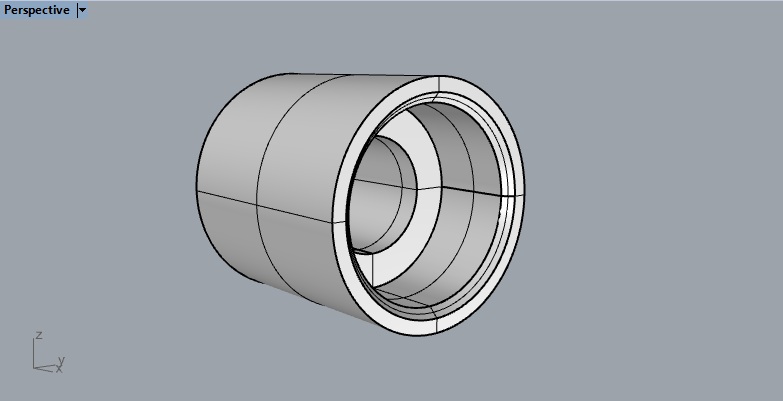

This time we want to use the G71 Canned Cycle to produce a bore in a piece of tube (or a solid with a pre drilled hole.

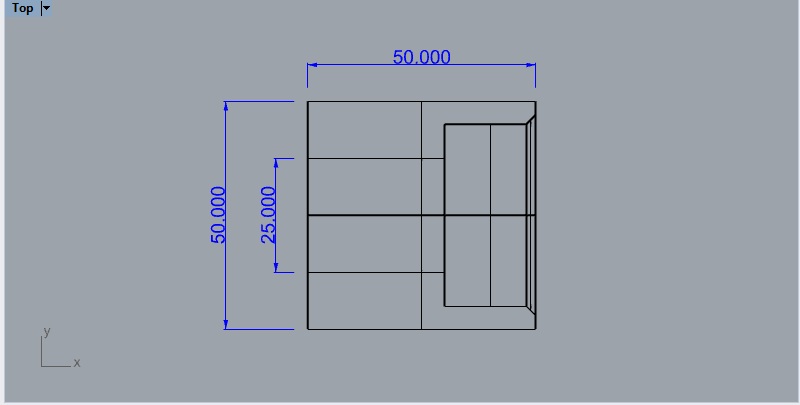

From the top what we want is this.

We have a 50mm diameter bar with a 25mm hole in it with the front counterbored and chamfered.

To see where we are working differences I have changed the relevant details to RED

- G00 X24.0 Z3.0

- G71 U2.0 R0.5

- G71 P100 Q200 U-0.5 W0.0 F0.25

- N100 G00 X44.0

- G01 Z0.0

- G01 X40.0 Z-2.0

- G01 Z-20.0

- N200 G01 X24.5

You will see that our first move is to the smallest part of the job, the first N line moves the tool to the largest part of the job. The U value in the 2nd G71 line becomes a MINUS to ensure the correct amount is left for finishing.

Remember P + Q are drawing what you want to end up with. Now you have at least a basic Canned cycle under your belt. Keep going, it gets easier with time.