So what are container programs?

Typically there are a limited number of operations a CNC lathe will carry out, “Round and Shiny’s” I call them at work, When you have only 2 axis available on a machine, what you can do may well be impressive but it’s also quite limited so many operations will remain the same with only dimensions changing.

Do you desperately want to type up all the same shit time and time again? not really. Have a look at the following pics of items and you will see what I mean.

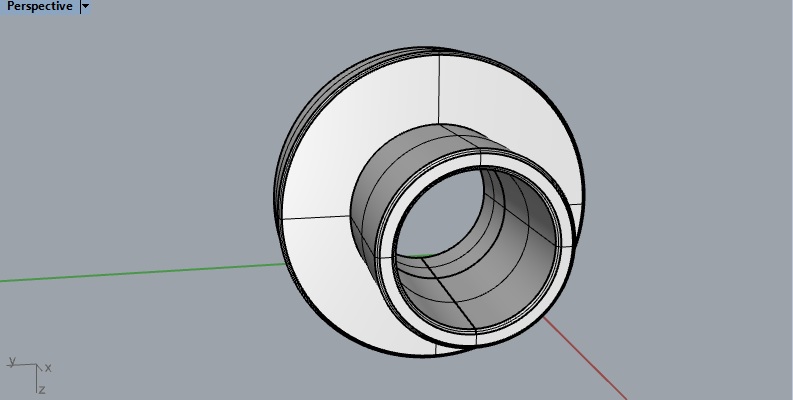

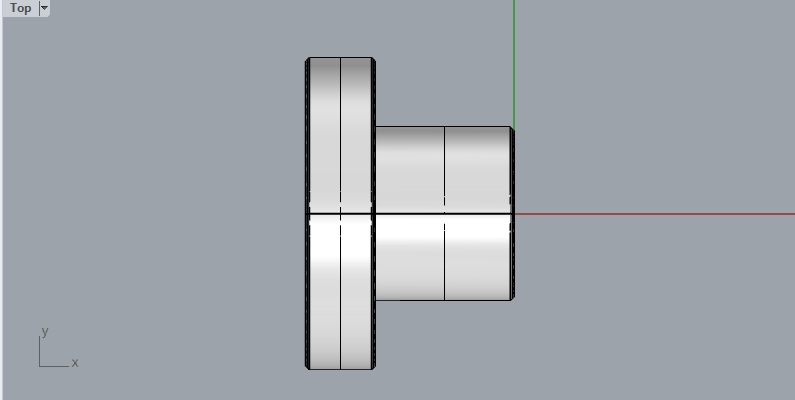

First one is a top hat bush, probably Brass or Phossy Bronze.

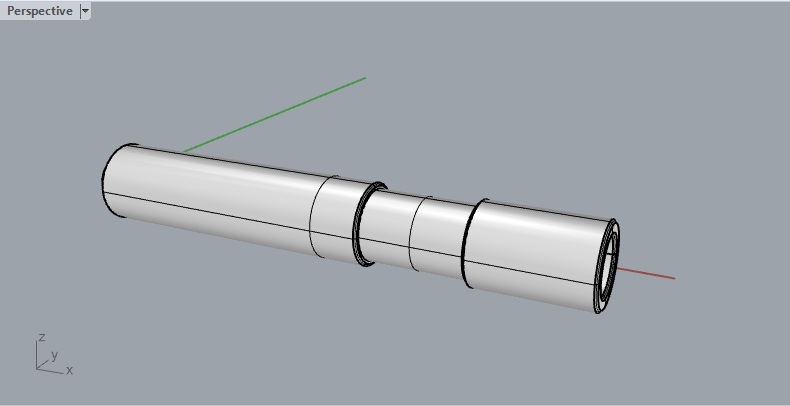

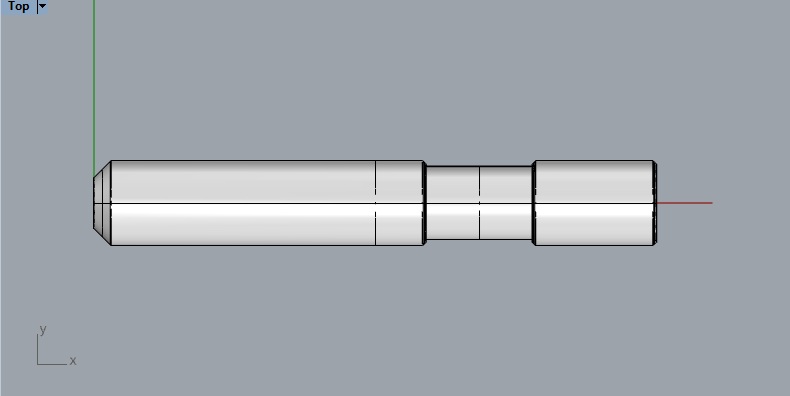

Now we have a counterbored retaining shaft.

Yep, different items but the program we use to make them won’t differ very much. For the top hat bush we will have

- Rough Face + Rough Turn OD

- Drill (U-Drill or Eco Drill)

- Rough Bore ID

- Finish Face OD

- Finish Turn OD

- Finish Bore ID

- Back Chamfer + Part Off

There will be variations depending on what tool, for example you can drill and bore with single point eco-cuts but the principle is as above.

Now for the shaft:

- Rough Face + Rough Turn OD

- Drill (U-Drill or Eco Drill)

- Rough Bore ID

- Finish Face OD

- Finish Turn OD

- Finish Bore ID

- Wide Groove Middle Section + Back Chamfer + Part Off

At the start of your program you will have a series of codes, global’s and declarations that will remain the same, during the program you will still be using sharp things going round and round with only the speed and maybe feed changing. Why re-write all of that? Just delete the bits you don’t need and change the dimensions to what you do need sequentially from the top of the program to the bottom in Edit mode. No running back to the PC to write the code, no dumb assery using CAD/CAM + Post Processing (really? for two f**king axis?) just get on that control pad and make the changes on the machine. Keep a range of programs in the machine with say 6 or 8 operations, then just edit that unless it’s something you will do again. If so just give it a different program number and save it to the USB Stick / PC / Memory Card. Had this conversation with Gary at work this week and even though he has had limited time on G-Code machines in our last place he did exactly this (we have worked together before our current jobs), edit what you got and re-use it. Personally I think it’s often the best way to learn.

Coding direct on the controller (Known as “Online” programming) ,while it makes your arm ache if you are tall like me, is great experience and helps you learn more easily.

Don’t forget, even older Fanucs have simulation / Graphics you can use to see if you have dramatically screwed up.

With this in mind I’ll post some generic “Container Programs” when the code pages are finished so you can copy and paste or just download the .NC files themselves to use as you wish.