Gee Zero Nine: Absolute Stop (Precision Stop)

G09 Commands the machine to decelerate to Feed 0 at a corner or position change to enhance perfection in edges for 1 revolution of the chuck. (Explanation below)

Syntax:

G09 X*.* Z*.*

- X*.* being an axis

- Z*.* being an axis

Explanation: CNC Axis are often big chunks of metal that move both in Rapid and Feed modes at considerable speed. The laws of Motion come into play here, anything moving has kinetic potential, a car, a cricket ball or whatever. Once an object starts to move it will always *want to continue to move in it’s current direction unless acted upon by an opposing force. A good example is when you borrow Dad’s car, off out for the evening and think you are Ayreton Senna when you get to a 90 degree bend. You want to turn hard left but the cars potential energy wants to keep going the way it was already going. End result ? unless you attempt to slow down (reduce the cars potential energy) you are going to be explaining to angry Dad why his new Ford Focus no longer has anything past the rear wheels.

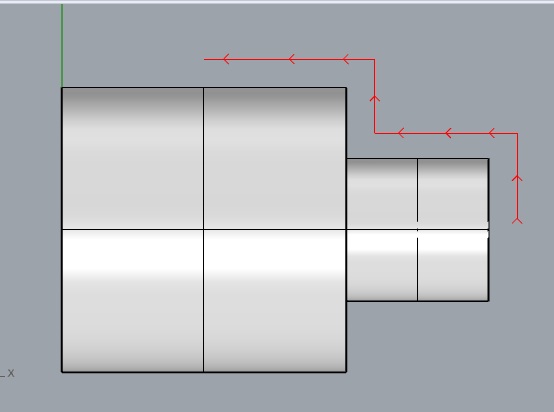

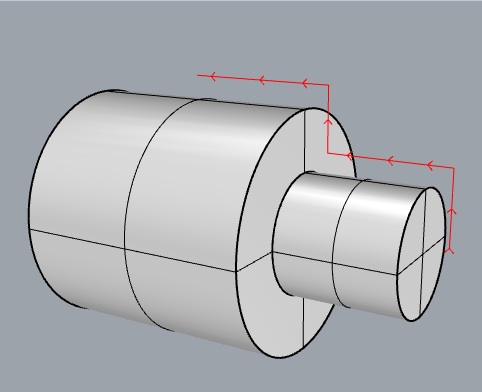

So back to the machine, the tool (and it’s turret) are moving at speed and they want to keep going when you want to turn 90 degrees at a corner. In the picture below the tool is moving in the direction of the red arrows.

Programmed tool path.

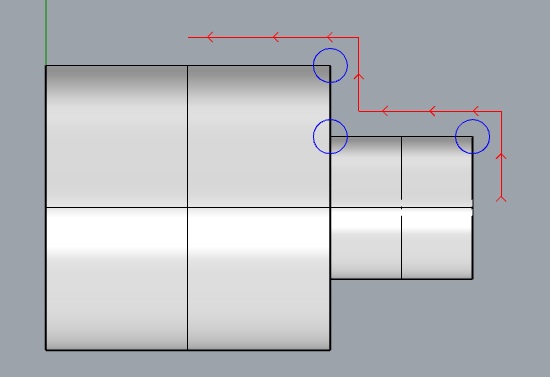

The problem is on the corners shown by the blue circles below.

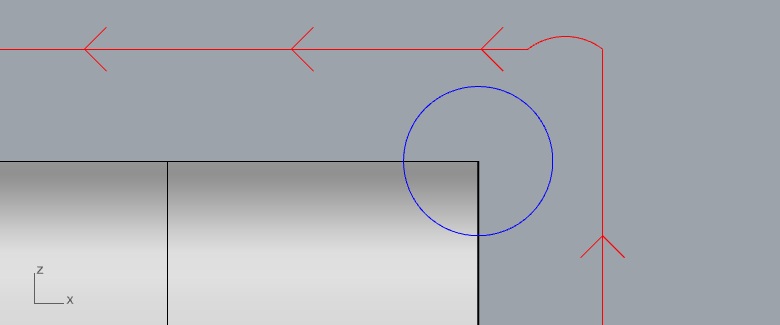

If you take things to finite detail at those corners the tool turret / axis is going to experience forces that try to fight back against that energy causing something like the following.

To get a more accurate corner without the wobble the G09 command causes the axis to decelerate and come to a complete stop at the corner point for 1 rotation of the chuck, before moving on to the next position. This will give as near perfect a 90 degree corner as you can get. This is executed so quickly you will not notice (Think of a spindle doing 4,500 RPM, that’s 75 revolutions per second, or 0.0133 seconds per revolution).

On small diameters this *corner wobble is more likely to show up at those higher revs than on large diameters where the axis and spindle will be moving more slowly. Are you really likely to use this function in the day to day world? probably not, but at least now you know what it does.

G09 Is A Non-Modal Command